While it hasn’t often come across on this blog, due to most of the focus being on architectures of control, I am, both personally and professionally, very interested in lightweight transport – its design, use and potential.

‘Lightweight transport’, by my reckoning, includes anything where the intention is to transport people or goods from one place to another ‘efficiently’ – in truth, I’ve always been interested in all forms of transport (and the industrial-business complexes behind its development and manufacture) but the engineer in me is most excited by innovative ways of using as little as possible to achieve as much as possible, and in most cases, this comes down to a ‘lightweight’ mindset.

As a designer, I’ve been lucky to be involved with a few lightweight transport projects for Sir Clive Sinclair, including some work on the A-Bike (the world’s lightest, smallest folding adult bicycle) under Daka‘s Alex Kalogroulis, and currently further development work in this vein with Ben Wilson. While at Daka I also gained some experience with the Sinclair WDU wheelchair assistance unit, which inspired me to experiment with my own series of larger wheelchair drive systems, learning, practically, a bit about electric motors along the way, and becoming increasingly convinced of their potential (no pun intended).

But I’ve never tackled anything car-sized. I’ve researched and written about Reliant, one of the world’s most significant lightweight motor vehicle innovators, but have never actually designed or built something of this size. (Certainly, I’ve thought about, and sketched plenty, since I was in primary school.)

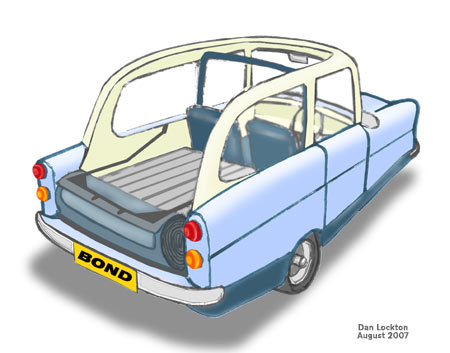

A stepping-stone towards this would be to modify (and improve, by some definition) an existing vehicle, and various factors, in combination, have inspired me to envisage tackling an electric conversion of a Bond Minicar, also (perhaps) giving it a full-length roll-back roof to produce a kind of convertible pick-up, with the batteries under the floor – to produce something like that shown in my sketch above.

The project is a very tentative idea at present, but in the next few months I hope to elaborate on what it will involve, what the technical problems are, and how I aim to go about solving them – along with an explanation of my rationale, before actually proceeding (or not). Briefly: if I can do this well, I will end up with one of the most practical vehicles possible for the near future: an ultra-manoeuvrable, ultra-light, tax-exempt, Congestion Charge-exempt, corrosion-resistant electric utility vehicle costing just pennies to run and great fun to drive.

2 Comments